MGA is a forerunner in the automation and digitalization of engineered solutions for life science manufacturing

CAPABILITIES

CAPABILITIES

At MGA, we anticipate our global clients' automation and digitalization challenges, advancing actionable, future-proof, sustainable execution. We have been proven to deliver quality and efficiency in both projects and services, across the primary process of life science manufacturing. This is founded on our:

- Position as process owner within our sector.

- Pioneering know-how in automation and digitalization based on R&D and innovation.

- Internal team of industry specialists with many years of experience.

- Technical, innovative capacity to generate robust solutions.

- Distinctive international expansion strategy.

We also work hand-in-hand with other Masco Group brands, building a globally integrated offer that enables clients to bring life-changing products and services to patients.

PLATFORMS AND SUPPLIERS

PLATFORMS AND SUPPLIERS

MGA focusses on creating a competitive advantage for our customers, with reliable and future-proof solutions.

We aim to protect the investments of customers by adopting state-of-the art technology based on first class vendors, renowned for their innovation and ingenuity.

Our automation, process control and digitalization solutions use established platforms and enable us to deliver for clients worldwide.

Our main adopted vendors are:

- Siemens

- Rockwell

- Mitsubishi

- GE Digital

- Every leading technology in its class

MEET THE TEAM

MEET THE TEAM

We work hand-in-hand with other Masco Group brands, delivering a globally integrated offer that enables clients to bring life-changing products and services to patients.

At MGA, we have built a unique, multi-disciplined team of specialists in pharma and biotech applications. This includes talented automation engineers, reliable process experts, smart data scientists and dynamic service field technicians.

Together, we combine our experience and technical capabilities to deliver robust solutions. We always ensure the best fit for our customers, securing investment over the entire lifecycle of the plant.

MGA supports clients to meet their time-to-market deadlines by adopting the most effective and suitable approach. We look forward to introducing you to our passionate team of specialists.

Ask a Masco Group Automation expert to find out how we can support you in your mission.

MGA generates smart, integrated solutions based on understanding the ever-changing client requirements and industry regulations.

MODERN

AUTOMATION

SOLUTIONS

Modern Automation Solutions

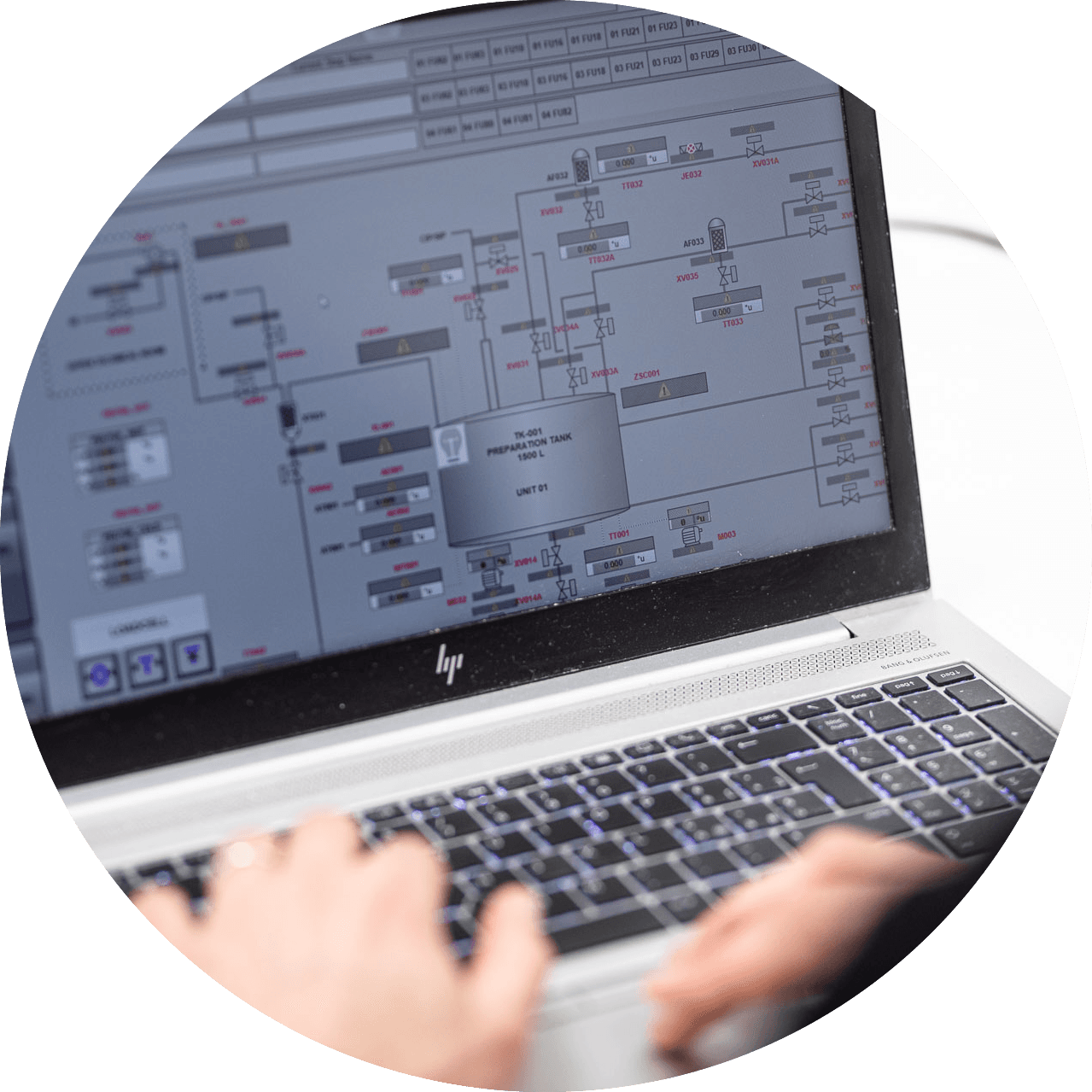

Starting from conventional solutions, based on PLC, HMI or SCADA systems, our technology evolves towards a more modern and systematic approach.

UX is moving significantly toward scalable solutions, web-based and zero-installation clients. Modern interfaces are portable, from computer to tablet to smartphone screens.

We see the adoption of extensive standardisation and low-coding, based on control modules types, aiming at maximum modularity, to reach the MTP (Modular Type Package) standard, which will be a game changer.

Automation is no longer the writing of software, but using standard modules which can be orchestrated at an higher level.

PROCESS

CONTROL

Process Control

We know that when control strategy becomes complex, a process control system based on DCS technology must be applied. Working with standard libraries, the software design connects standard blocks, automatically generating the application, providing a solid result.

New web-based platforms are also coming, where concurrent engineering will provide a further advantage. The scalability and the expandability of these systems is mandatory, letting the control system grow together with the plant.

Our next-level approach involves the standardisation of the equipment and tracking of production process through a graphical interface, alongside batch management, which is fully compliant to the ISA-S88 standard.

DIGITAL

TWIN

The Digital Twin of the Plant

The 'Industrial Metaverse' is around the corner.

Plants can be simulated and modelled with extreme fidelity.

This allows our team at MGA to:

- Provide a real-time model of the plant to perform testing or even commissioning.

- Use a Digital Twin, together with virtual controllers and HMI's, to train the operator and the maintenance crew, without any risk of accidents or damages.

- Provide realistic data from the model, to train a machine learning algorithm.

- Have a solid basis for process optimization, increasing productivity, improving performance, and reducing losses.

IIoT &

ARTIFICIAL

INTELLIGENCE

IIoT and Artificial Intelligence

All improvements are based on analysis of historical data.

With the IIoT - Industrial Internet of Things - we collect data and store it in an Edge or Cloud system, through encrypted and secure connections.

This huge amount of data allows the aggregation and retrieval of information. From bytes to KPI's, the user can deliver the best for their plant:

- Increasing efficiency

- Reducing downtime and increasing availability

- Optimizing the maintenance strategy

- Increasing the product quality and avoiding losses

This general approach can be declined through multiple points of view:

- Product

- Machines and plant

- Production processes

- Operation management

- Supporting the decisions of the management

PAPERLESS

MANUFACTURING

Paperless Manufacturing

The production process and optimal control strategy for machines and plants today is just part of the story.

The Enterprise Resource Planning, managing finance, sales orders, warehouse, deliveries, and invoices, is logically and physically connected to the production process.

Any sales order must be translated into a production order, scheduled according to the delivery date and availability of resources. Whatever is produced has to be reported to the ERP to be delivered and invoiced. At the same time, we report the costs related to the product, which can be energy, raw materials, waste and scraps, or maintenance costs, collecting the quality and tracking data to give empirical insight into the produced goods.

Today, everything is tracked, recorded, and kept under control, according to transparent workflows, in a digital process.

We are always looking for talented engineers, able to contribute with energy and enthusiasm, and an open-minded, innovative mindset.

MGA is an exciting environment, where our people are free to express their capabilities and performance is always rewarded.

If you're ready for the challenge, start a new journey with Masco!